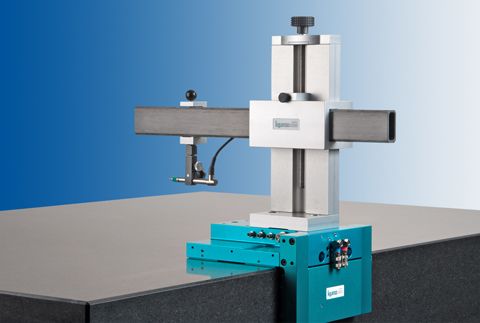

The measuring slide has been equipped with our approved vacuum air bearing system, where the guide way surfaces are held by vacuum and simultaneously being accurately lifted off with a precise air film. The STRAIGHT-lite is now held with a fine break in its position without affecting the air film. The air unit SA 100 is required for the processing of air pressure and the generating of vacuum.

Kunz precision AG is a leader in the revision and calibration of hard stone test plates and test equipment.

Flatness of the guide surfaces: recommended quality DIN 876/00.

For special solutions or other sizes please contact us: Contact.

To make measuring with the measuring device STAIGHT-line even more easy and efficient, you can order the CARBON-stand as a practical option. The bracket is adjusted to the correct height on the vertical column with knurled screws, and then clamped in the correct position.

Details